Krempel has many years of experience in the production of composite materials and high-performance components. With our comprehensive engineering expertise in the fields of fibres, resins and processing technologies we can produce not only surface materials but also semi-finished products and components in our sophisticated production facilities.

Fibre composites

Krempel’s diverse product portfolio:

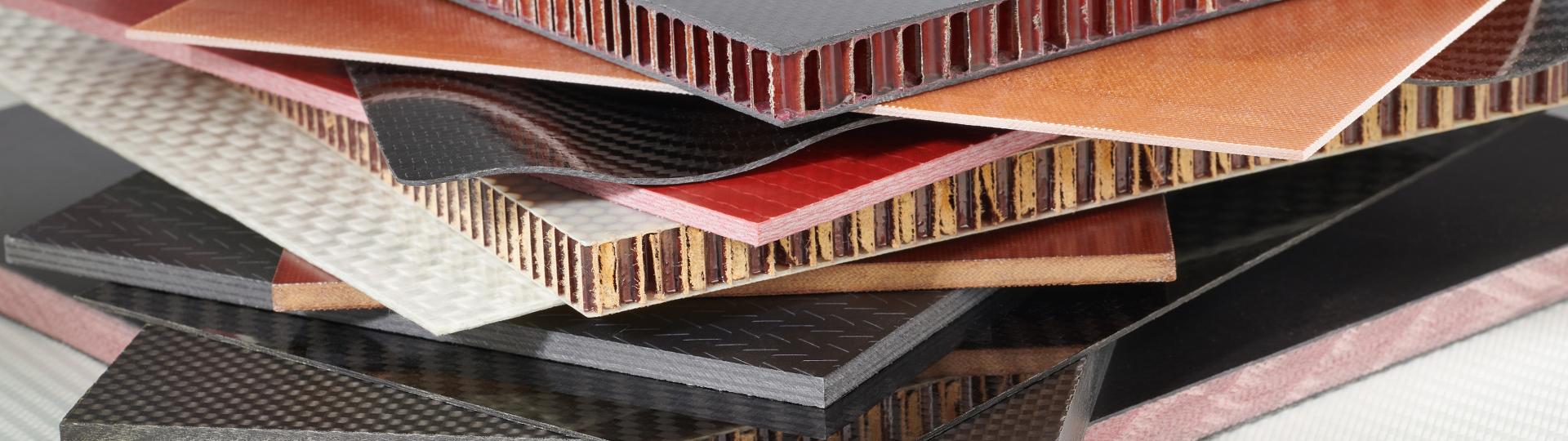

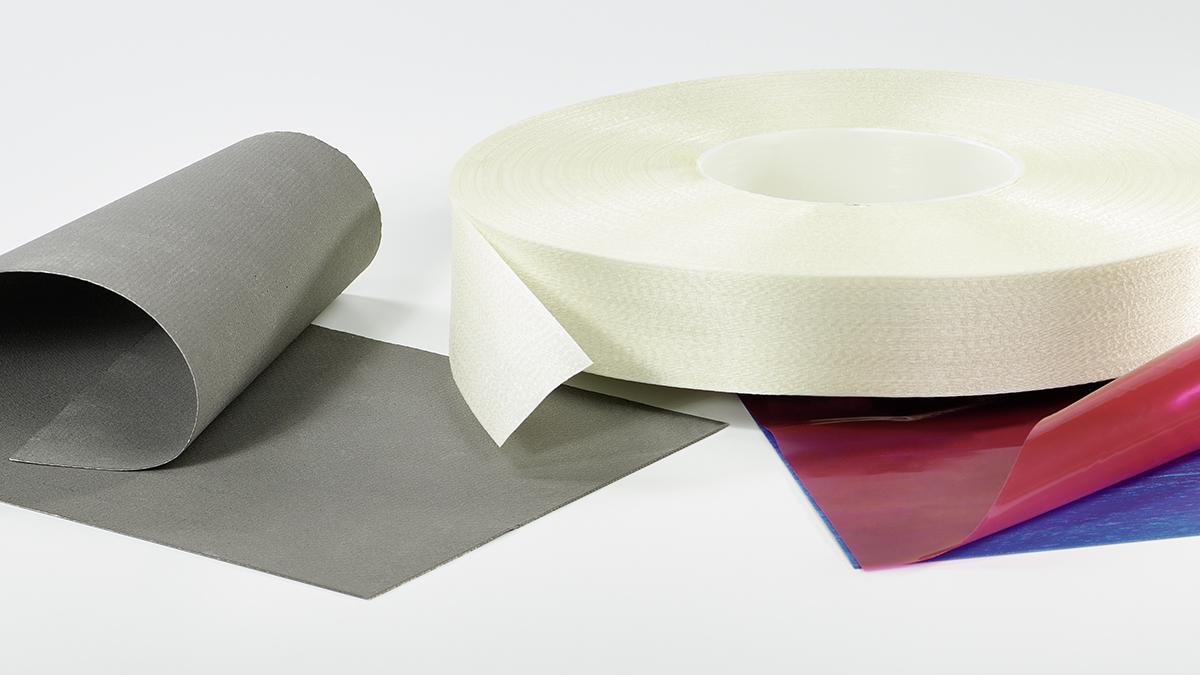

- Prepregs & UD prepregs

- CFRP/GFRP laminates

- CFRP/GFRP components

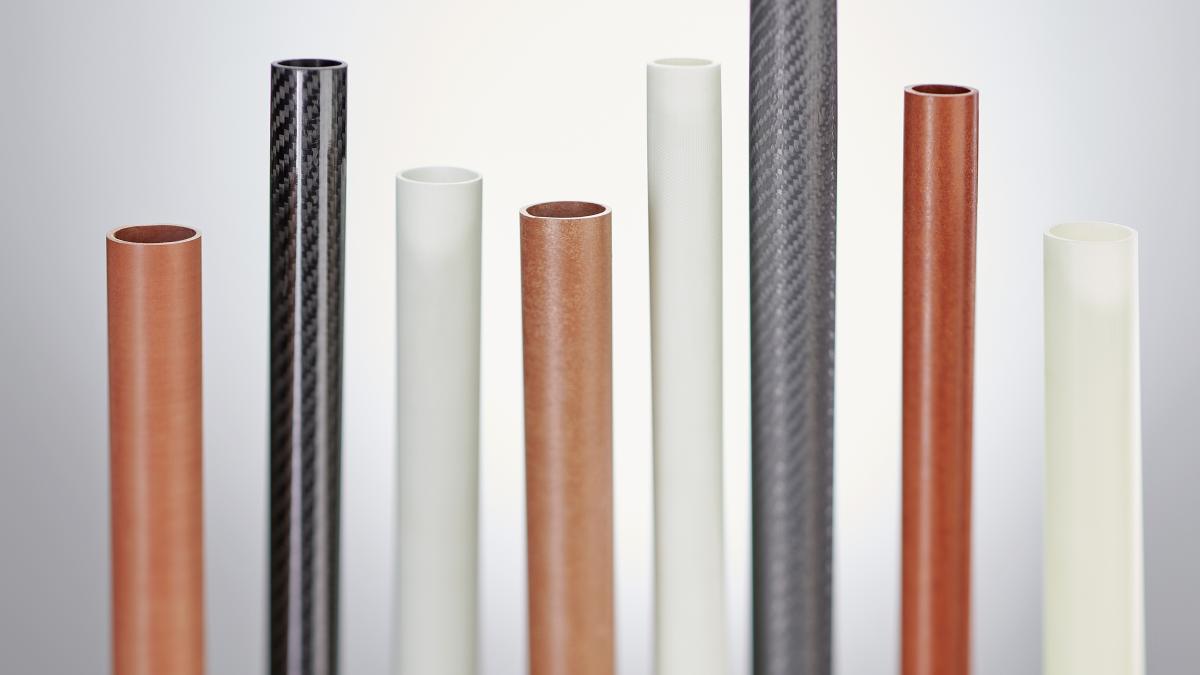

- Fibre composite tubes

- Pultrusion profiles

Krempel is a leading manufacturer of fibre composites, and we provide our customers with comprehensive support, from material selection, engineering and prototyping right through to series production.

Whether glass, carbon or aramid fibres, or even natural fibres, our woven and non-woven fabrics, rovings and non-crimp fabrics are impregnated with the right resin system for your product.

We provide the impregnated surface material as a raw material, or pressed into plastic sheets and mouldings or plastic profiles. The production of special profiles is one of Krempel’s strengths.

Other Krempel specialities include the winding reels and laminated tubes that are produced on our filament winding systems and convolute winding systems.

Just ask - we would be delighted to advise you!